Home » Pallet Racking Height

Pallet Racking Height

Considering Pallet Racking Height

To determine the height of pallet racking, you should combine factors relating to the forklift truck, the goods, the pallet and the building.

Fork Truck Capability

Here is an example of a forklift showing the ‘height of the lift’ as generally described by forklift truck manufacturers. The thing to note is that they define the height of the lift as the height to the top of the forks when the mast is fully extended, down to the ground.

Pallet Racking Height Explained

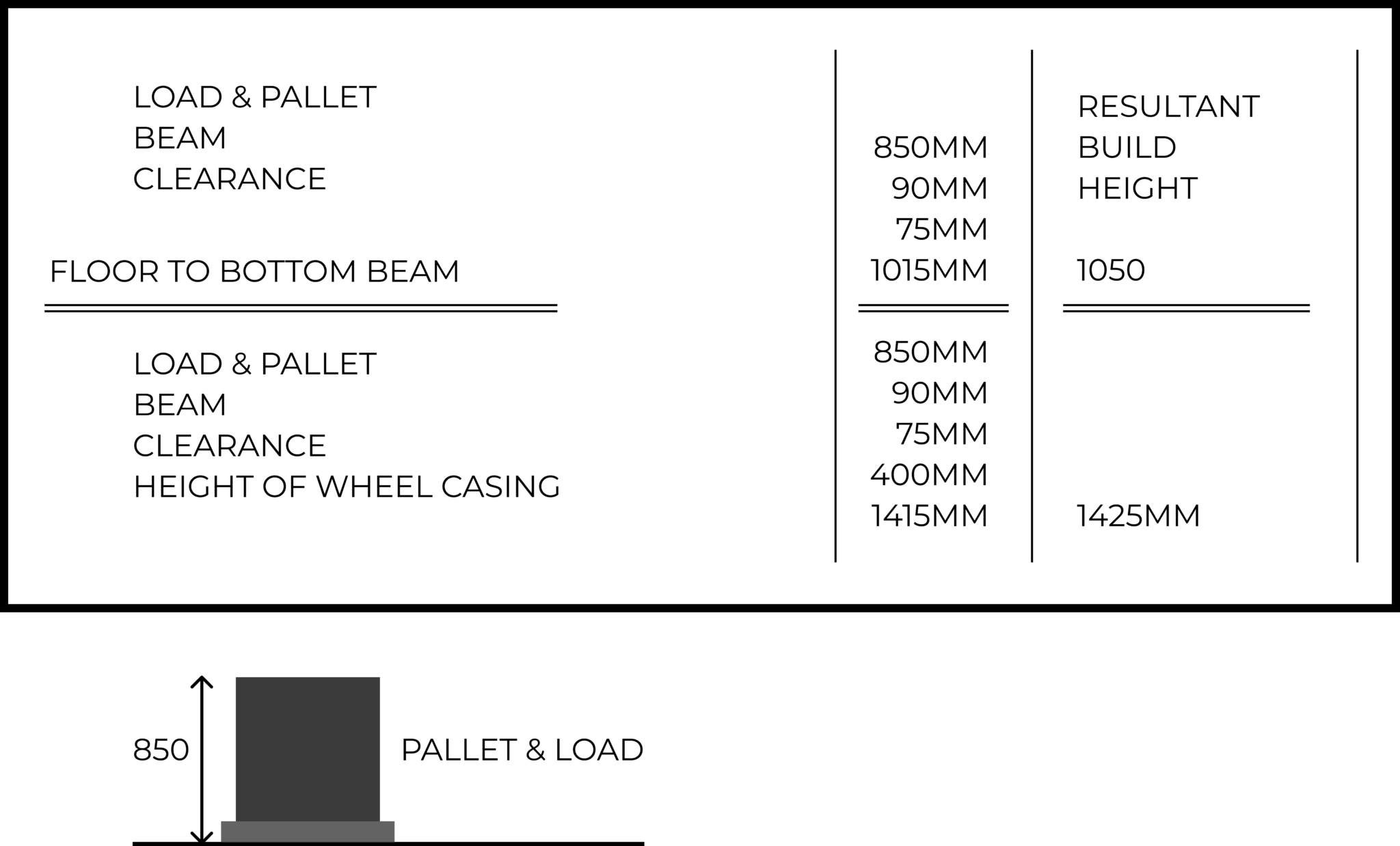

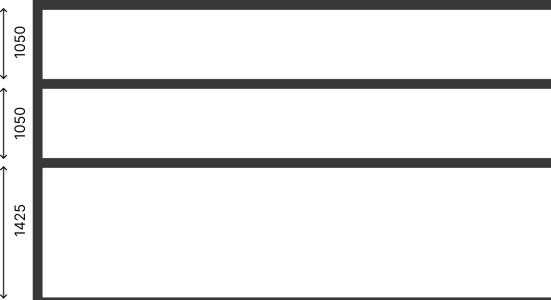

Let us translate this into practicalities. The pallet sits on the forks, the forks support the underside of the top timbers, thus there is a 125mm of pallet hanging below the top of the forks. In addition, allowance must be made to clear the beams. This allowance increases with the beam height. The actual amount can be seen in Column B, in the left-hand panel in Fig. 2.

This means that the sum produced must be taken off the truck manufacturers maximum lift height to calculate the height at which you can put in the top beam.

Forklift Truck Heights and Loads

Some forklift trucks have parts extending above the height of the forks. The forks are supported by the mast. Sometimes there are load guards fitted on top of the mast to prevent accidentally dislodged goods falling back onto the driver.

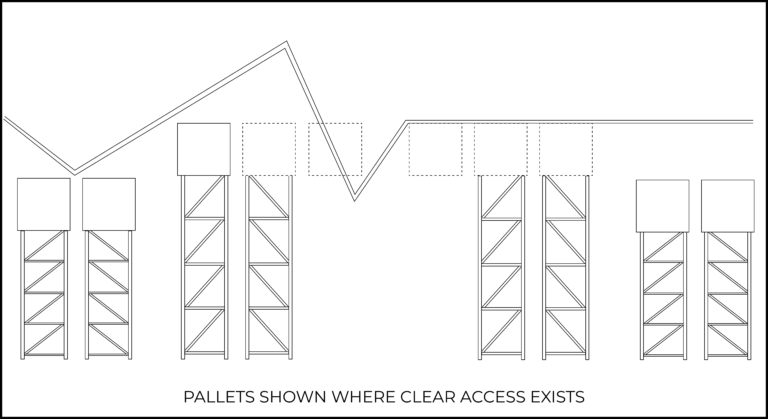

Loads rarely exceed the height of the parts of the forklift truck extending above the top level of the forks. When working out a layout, care must be taken as to whether the pallet and its load are higher than those parts above the fork.

Forklift Trucks with extending masts

Many forklift trucks have extending masts, usually denoted by the term double or triple mast, or duplex or triplex mast. They also have what is known as ‘free lift’, when used with these masts. What this means is the forks travel up the mast for some height before the mast starts extending.

It is possible that a user may have a forklift truck with a double or triple extending mast, but is using it in a comparatively low ceiling situation. On these occasions, it is quite possible that the mast itself will be higher than the load and care must be taken about this point.

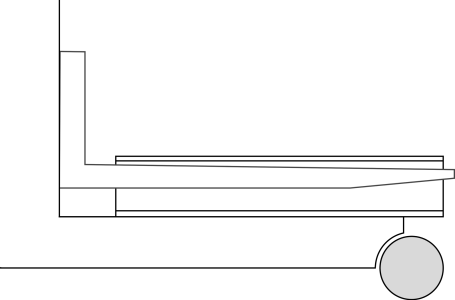

Most forklift trucks used with pallet racking are either ‘reach-trucks’ or ‘narrow-aisle trucks’ (which are based on the reach-truck construction). In conjunction with pallets, care must be taken when calculating the clearance from the ground to the underside of the first beam level. When the mast is retracted, the pallet must sit on top of the wheel casings, so it is already above the ground at this point.

As the mast is extended forward to put the load into the rack, the pallet will travel at this height above the ground.

It is not until the pallet is fully enclosed within the rack that the forks can be lowered to the ground. So, in addition to the clearance between the top of the load and underside of the beam, clearance must be allowed for the wheel casing, plus the height of the pallet above the wheel casing.

Of course, the forks can be extended with their load in the gangway, before the pallet is placed within the rack. This increases the width of the gangway because in effect the truck is being used as a conventional counter-balance truck.

The whole point of the reach truck principle is lost on these occasions. Normally increasing the height from the ground to the underside of the first beam level is the most cost-effective way of using the space available.

Door Sizes

The height of doors through which trucks will travel is critical. Frequently, even when the forks are in a closed position, the height from the ground to the top of the mast can be over 2,400mm. Many doors are 2,400mm or 2,100mm high.

Roof Heights

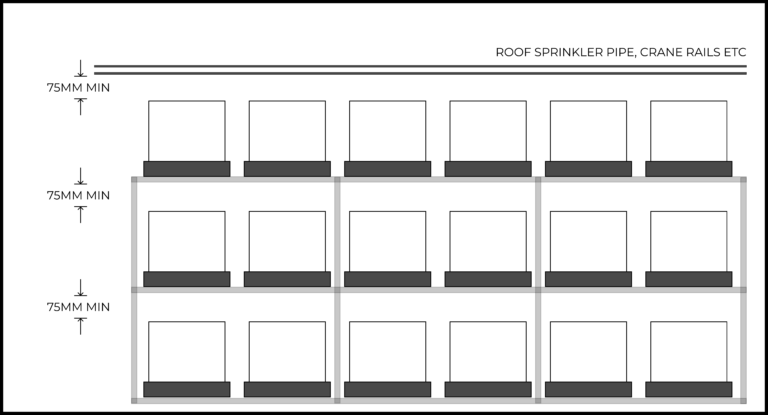

The other clearance in the roof that may need to be considered is, if sprinkler systems are required.

If you are measuring up a partially completed warehouse, remember the sprinkler systems, steam pipes, electric trunking and lighting, all tend to be among the last of the services put into a building. So it’s possible that when you measure up the building these services will not yet have been installed. (These comments apply to control boxes located on walls and columns, too.)

And on lower beam levels, 75mm min. Clearance is required between the top of the pallet and the load to the underside of the beam above.

So, How High?

If a survey was carried out on all of the forklift trucks available it would be found that the height of the lift for fork lift trucks with a simple, single mast, would be in the range of 3m to 4m, the trucks with a double or duplex mast would be in the range of 5m to 6m and trucks with a triple or triplex mast would be in the range of 7m to 8m.

However, before the height of the racking can be determined, you should consider the load and the building.

Unless a building has been purpose-made for warehousing it is rare indeed that the height to the eaves is greater than 5m.

Assuming that a load plus the top of the pallet is about 1m high, and that we use a simple mast truck, the height of the top of a fully lifted load will be in the order of 4m to 5m.

The ever increasing height of warehouses, increase in racking height and number of subsequent storage levels, imposes ever greater loads on the floor, that must be considered.

RediRack are full members of SEMA (Storage Equipment Manufacturers Association), with our installation and inspection teams fully SARI (SEMA Approved Rack Inspector), and SEIRS (Storage Equipment Installers Registration Scheme) registered.