Home » Different Types of Pallets

Differences Types of Pallets and their Purposes

RediRack understands that choosing the right type of pallet to use for your warehouse can be difficult so we have produced a quick guide below to give a basic overview of the different types of pallets and their purposes.

Two-Way Entry Pallet

Here the bearers permit the entry of forks or fingers from two opposite directions only. The sides through which the forks enter are called “entry sides”.

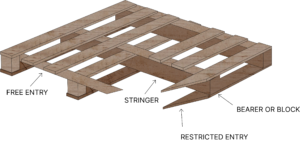

Four-Way Entry Pallet

The bearers (or blocks) permit entry of forks or fingers at each end and each side. The sides through which the load wheels of a pallet truck can pass without leaving the ground are known as “free entry sides”. The other sides, where the load wheels have to pass over the bottom slats are termed “restricted entry sides”.

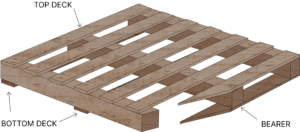

Bearers

Members under the top deck or separating the top and bottom decks that provide a space for the entry of forks or fingers. They may consist either of longitudinal members or distance pieces (usually known as blocks)

Chamfer

A rebated angle in the structure of a pallet, in particular on the edges of the bottom deck, to facilitate the passage of the load wheels of a pallet truck.

Deck

The top or bottom flat surface which may be solid or otherwise.

Entry Members

Members forming the outside edges of decks on the sides in which the forks or the fingers enter.

Stringer

Entry

Space permitting the entry of forks or fingers in a particular direction.

Wings

Those parts of the deck or decks which project beyond the bearers.

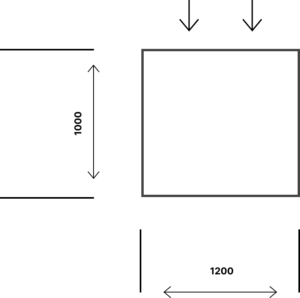

Standard sizes for flat pallets

The British Standards Institution has selected the following plan dimensions for standard pallets: 800mm x 1200mm, 1000mm x 1200mm, 1200mm x 1200mm, 1200mm x 1800mm, (B.S.2629 1967).

The international organisation for standardization has also recommended the above sizes and proposed the following plan sizes as international standards for maritime use:

1200mm x 1600mm and 1200mm x 1800mm

These standard plan sizes take into account the majority of transport vehicles and are designed to give the best practicable loading on general purpose vehicles, provided the pallets themselves are loaded to capacity.

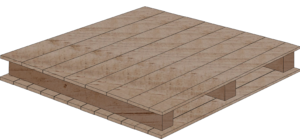

Two-Way Entry, Singled Decked

A pallet with only a top deck. Suitable for items which can withstand the concentrated loads imposed by the bearers, during stacking, e.g. wooden boxes and drums. Also used where little stacking is required and for storing unit loads in pallet racking when the bearers are supported by the rack framework. Shown here with an open boarded (slotted) deck.

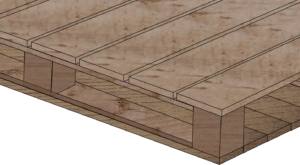

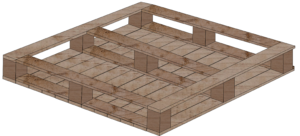

Two-Way Entry, Reversible

A pallet with similar top and bottom decks, either of which will take the same load. This gives even distribution when stacking. Shown here with a close boarded deck.

Note: Not suitable for pallet trucks.

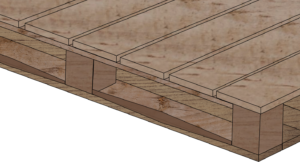

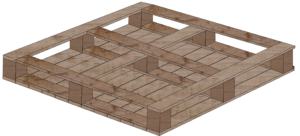

Two-Way Entry, None - Reversible

For multi-tiering. The bottom slats add to the strength of the pallet and provide a larger surface area, therefore giving a less concentrated load distribution.

Shown here with an open boarded (slotted) deck.

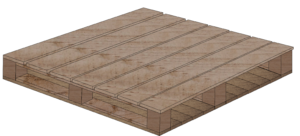

Two-Way Entry, Reversible Winged

The decks extend beyond the outer bearers for lifting purposes, e.g. by crane with spreader-bar slings. Similar top and bottom decks either of which will take the same load. Even load distribution when stacking. Shown here with a close boarded deck.

Note: Not suitable for use with pallet trucks.

Four-Way Entry, Non-Reversible

A Pallet has bearers which permit the entry of forks or fingers from either side or end. This can be of advantage in block stacking operations. Only suitable for items which can withstand the concentrated load imposed by the bearers when stacking.

Shown here with a close-boarded deck.

Two-Way Entry, Perimeter Base

The bottom slats are so arranged as to present a level bearing surface, thus giving a less concentrated load distribution when stacking.

Shown here (Inverted) with a close-boarded deck.

Four-Way Entry, Perimeter Base

Four – way entry, having the bottom deck so arranged as to present a level bearing surface compatible with hand pallet truck usage, and giving a less concentrated load distribution when stacking. Shown here (inverted) with a close – boarded deck.

Four-Way Entry, Cruciform Perimeter Base

The ‘cruciform’ design of the bottom slats adds to the strength of the pallet and improves load distribution when stacking. The most widely used type of four – way entry pallet. Shown here (inverted) with a close – boarded deck.

Four-Way Entry, Reversible

A pallet with similar top and bottom decks, either of which will take the same load. Gives an even load distribution when stacking. Shown here with an open-boarded deck.

Note: Note suitable for use with pallet trucks.

Two-Way Entry, Non-Reversible Winged

A Normal two-way entry pallet but with the deck extending beyond the outer bearers for lifting purposes. eg. by crane with spreader – bar slings.

Shown here with an open – boarded (slotted) deck.

Four-Way Entry, Reversible, Winged

Similar top and bottom decks either of which will take the same load. Even load distribution when stacking. Both decks extend beyond the outer bearers (blocks) for lifting purposes. eg. by crane with spreader bar slings. Shown here with an close-boarded deck.

Note: Not suitable for use with pallet trucks.

The advantages of storing pallets with the front to back runners resting on the beams enables the front and rear, left to right cross members to act as a locking device so that pallets cannot be accidentally dislodged, However, it does mean that the front to back members must be substantial, which virtually eliminates four-way entry pallets.

Locating uprights on the beams as show in sketch 2 permits the pallets to be enclosed within the perimeter of the rack. However, the width of the beam is only 50mm so if the fork lift truck driver fails to put the pallet fully into the rack there is a danger he will miss the back beam, causing the goods to be dislodged, or if he puts the pallet 50mm too far in he will miss the front beam level, again causing the goods to be dislodged. One can visualise the damage that would ensue to the racking.

The vast majority of wooden pallets in the UK measure 1200mm x 1000mm (UK Pallet) or 800mm x 1200mm (Euro Pallet).

Consequently considering the two methods of loading pallets into racks as detailed before, the required beam centres are shown as follows. It can be seen why the 900mm and the 750mm wide frames have been established as standards.

Pallet Racking Considerations

Storing pallets with front-to-back runners resting on the beams prevents pallets from being accidentally dislodged. However, this method requires substantial front-to-back members, making four-way entry pallets nearly impossible to use.

Placing uprights on the beams, keeps pallets within the rack’s perimeter. However, the narrow width of the beam (50mm) means that the forklift operator must be precise in pallet placement, as any mistake could lead to dislodged goods.

In the UK, the majority of wooden pallets measure 1200mm x 1000mm (UK Pallet) or 800mm x 1200mm (Euro Pallet). As a result, beam centres have been set at 900mm and 750mm, based on the two loading methods described earlier. These centres accommodate the most common pallet dimensions and ensure efficient use of pallet racking systems.

Redirack, established in 1973 are dedicated to assisting you and your company with all your pallet racking requirements. From the initial design, manufacture, installation and moving onto pallet racking maintenance and racking inspections.

If you have any more technical queries, please take a look at our technical hub where we address frequently asked questions surrounding pallet racking.

Alternatively, if there is an issue we don’t cover, please contact us.

RediRack are full members of SEMA (Storage Equipment Manufacturers Association), with our installation and inspection teams fully SARI (SEMA Approved Rack Inspector), and SEIRS (Storage Equipment Installers Registration Scheme) registered.